Contacts:Mr. Liu

WahtsApp:+86 15154227700

Email:sales@qdhuazhu.com

Add:No. 5191 Beiershan Road, Tieshan Industrial Park, West Coast New Area, Qingdao City, Shandong Province, China

1、What is a steel wire shot blasting machine?

The equipment uses external power to pull and transport the wire through the cleaning room. It uses an

advanced high-efficiency and energy-saving blast wheel to throw out high-speed and dense shots beams

to hit the surface of the wire to remove the rust layer and oxidation on the surface of the wire. The skin and

its dirt fall off quickly, exposing defects on the surface of the wire and obtaining a clean surface with a

certain roughness.

2、The working range and production efficiency of steel wire shot blasting machine.

Wire product specifications:Ф4~Ф40mm

Maximum working speed:V≤60m/min (the user should adjust the speed according to the material)

3、Cleanliness of steel wire shot blasting machine.

Surface cleanliness of the material after cleaning: It complies with the requirements of the spray

cleaning level Sa3 in the GB8923.1-2011 standard, that is: when observing the wire after shot blasting

without magnification, there should be no visible oil, grease and dirt and should be free of scale, rust,

coatings and exogenous impurity. The wire surface has a uniform metallic color.

4、Roughness after shot blasting.

After the wire is shot blasted, the surface roughness Ra ≤ 3.0, and no new damage is allowed;

refer to GB6060.5-88 "Comparative Samples of Shot Peening, Sandblasting and Surface Roughness".

5、The noise of wire shot blasting machine.

Noise: ≤50dB (based on a distance of 1m away from the equipment), the noise should comply

with the "Design Code for Noise Control of Industrial Enterprises" GBJ8F-85. (The motor is basically

installed at the bottom, so the noise is smaller)

6、Design of Dust Collector for Wire Shot Blasting Machine.

The dust removal system flue adopts an overlapping design, which effectively prevents steel shot

from overflowing with the high-pressure airflow. (Our company’s unique design), it is also equipped

with a shots settling chamber, which further reduces the amount of steel shot overflow. (louvered overlap design)

Dust and noise must meet environmental protection standards. Indoor dust emission: ≤20mg/m3.

Implement the monitoring concentration limits for particulate matter (other) unorganized emissions in

Table 2 of GB16297-1996 "Comprehensive Emission Standards for Air Pollutants".

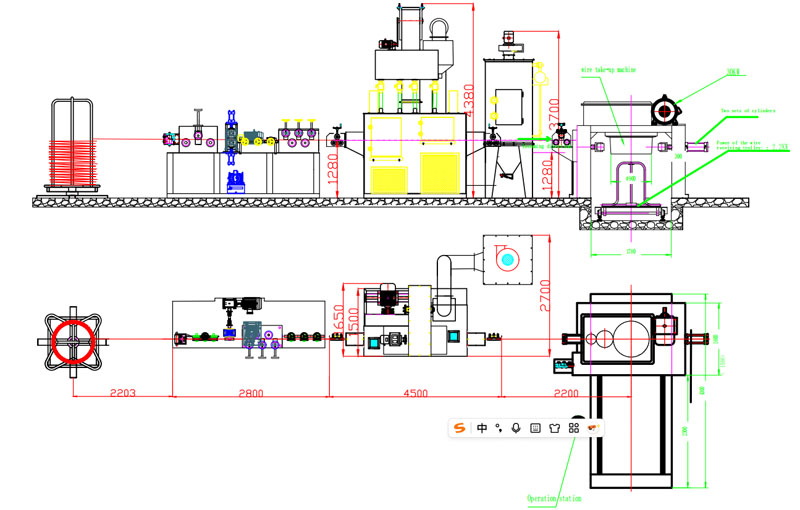

7、Composition of wire shot blasting equipment.

The main functional components of this unit are cleaning room, wire guide device, shot blast turbine,

shot circulation system (including elevator, separator, and flow adjustment device), dust removal system,

electrical control system and other components.

8、Technical parameters of wire shot blasting equipment:

No. | Item | Specification | |

1 | Wire diameter | Ф6mm~Ф30mm(Customize according to user requirements) | |

2 | Working speed | Wire processing speed: 0~120m/min (the speed is determined by the winding machine) | |

3 | Blasting quality standard | GB8923-88 A-B Sa2.5-3.0 | |

4 | Use abrasives (national standard cast steel round shot) | Diameter ≤φ0.3mm, hardness HRC45~50 | |

5 | Wire surface roughness after cleaning | Ra12.5μm | |

6 | Shots surface coverage | 100% | |

7 | Noise level | ≤80dB (A) 1 meter away from the machine | |

8 | Dust exhaust | ≤20mg/m3 | |

9 | Dust removal efficiency | 99% | |

10 | Hazardous substance content in workshop work area | Comply with the latest national standards | |

11 | Total air volume | 4500m3/h | |

12 | Power consumption total power | Power consumption total power | ≈86.5KW |

Total air consumption | 0.6 m3/min,0.45~0.6MPa | ||

13 | Machine overall dimensions (excluding dust removal) | Length: ~3900mm | |

Width: ~1800mm (excluding dust collector) | |||

Height: 4300mm (highest point of the elevator) | |||

14 | Height of wire inlet and outlet | 1280mm | |